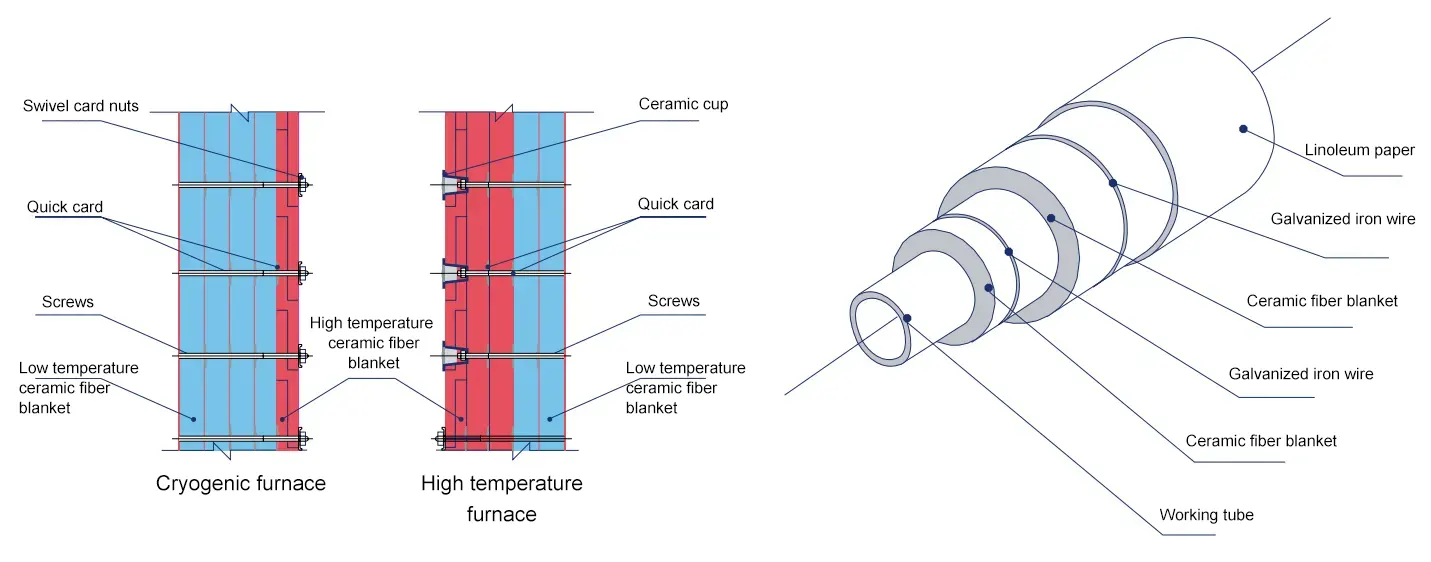

Fiber blanket serving for pipeline insulation:

The construction method of winding is adopted, in which the blanket is taken out of the packing box (or bag), unfolded it → cut according to the circumference of the pipeline periphery → wrapped around the pipeline → bundled with thin iron wire → constructed to the required thickness according to the same method → and protective treatment shall be carried out according to the requirements. Generally, glass fiber cloth, fiberglass, galvanized iron sheet, tar felt, aluminum sheet, etc. are used.

Requirement: The wrapped fiber blanket shall be tightly wrapped without gaps or leaks.

Cautions for execution:

* The fiber blanket should be cut using a straightedge and a sharp knife, and it should not be torn with force.

* Attention should be paid to protection during the construction of the fiber blanket. It is not allowed to trample or crush it.

* Necessary measures shall be taken to avoid being soaked by rainwater during the construction of the fiber blanket.

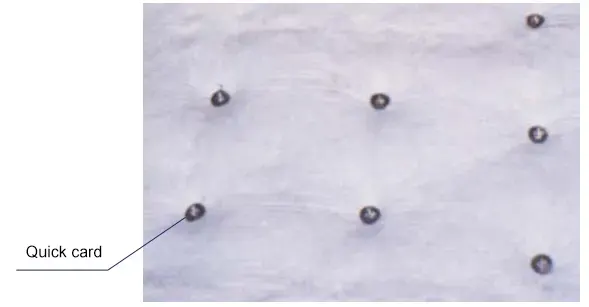

The construction method of the ceramic fiber blanket used as a backing is as follows:

Remove the blanket from the packing box (or bag), unfold it → cut according to the construction size using a straightedge and sharp knife → lay the cut blanket on the device → pierce the anchor through the blanket → fix it using metal cards → check the construction quality → lay it to the required thickness in order.

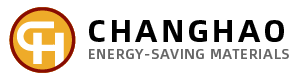

Fiber blanket used as wall lining: It should be fixed using ceramic cups or metal cards and nuts with the same temperature resistance rating as the fiber blanket, and the metal nuts and cards should not be exposed to the hot surface of the furnace.

Requirements: The butt joints between fiber blankets should be tight. The joints between layers should be staggered. The flat-laid fiber blankets should be compressed according to design requirements.