Ceramic fiber plate

Classification:

Ceramic Fiber

Key words:

Ceramic fiber plate

Ceramic fiber plate

[ Product Description ]

Ceramic fiber mould plate is made of ceramic fiber bulk as raw material, formed through vacuum process, and then specially processed. The product has a uniform structure, excellent heat resistance, and is applicable for engraving moulds.

Ceramic fiber firestop is a high-strength fiber board produced using specific refractory additives, this product has a tough texture, high compressive strength, superior high-temperature performance and excellent support; can be used as an industrial kiln temperature range of the firestop heat insulation of the excellent refractory materials.

Ceramic Fiber Mechanism Board adopts ceramic fiber cotton as raw material, made of vacuum forming, its strength is higher than that of fiber blanket and vacuum forming felt, suitable for applications that require rigid strength of the product.

In addition, according to the needs of the application, there are higher capacity vacuum forming ceramic fiber board products: the board's thermal insulation performance, wear resistance and strength have been further improved. Vitrified fiberframe and firestop formulations contain small amounts of organic binders to enhance their cold strength, which can be burned down during the first burn at approximately 200°C to 300°C. The organic binders can also be burned down during the first burn.

Translated with DeepL.com (free version)

[ Product Category ]

Standard Ceramic Fiber Mould Board Standard

Standard Ceramic Fiber Mould Board

High Purity Ceramic Fiber Mould Board

High Alumina Ceramic Fiber Mould Board

Zirconium Ceramic Fiber Mechanism Board

High Purity Ceramic Fiber Firestop

High Alumina Ceramic Fiber Firestop

[ Product Characteristics ]

● Low heat capacity, low thermal conductivity

● Non-brittle material, good elasticity

● Wind erosion resistance, long service life

● Excellent thermal stability and thermal shock resistance

● Rigidity, self-supporting plate

● Good resistance to spalling

● Easy to mold or cut

[ Typical Applications ]

Iron and steel industry: expansion joints, backing insulation, insulation sheets and mold insulation

Non-ferrous metal industry: intermediate ladles and runner covers for casting copper or copper-containing alloys.

Ceramics industry: lightweight kiln car structures and kiln hot surface linings, kiln temperature zones and fire stops Glass industry: melting pot backing insulation, burner blocks

Kiln construction: hot surface refractories (alternative blankets), backing for heavy refractories, expansion joints

Light industry: lining of combustion chambers in industrial and domestic boilers

Petrochemical industry: hot surface materials for the lining of high-temperature heating furnaces, molds for the molding of deep-processed products such as craft glass, etc.

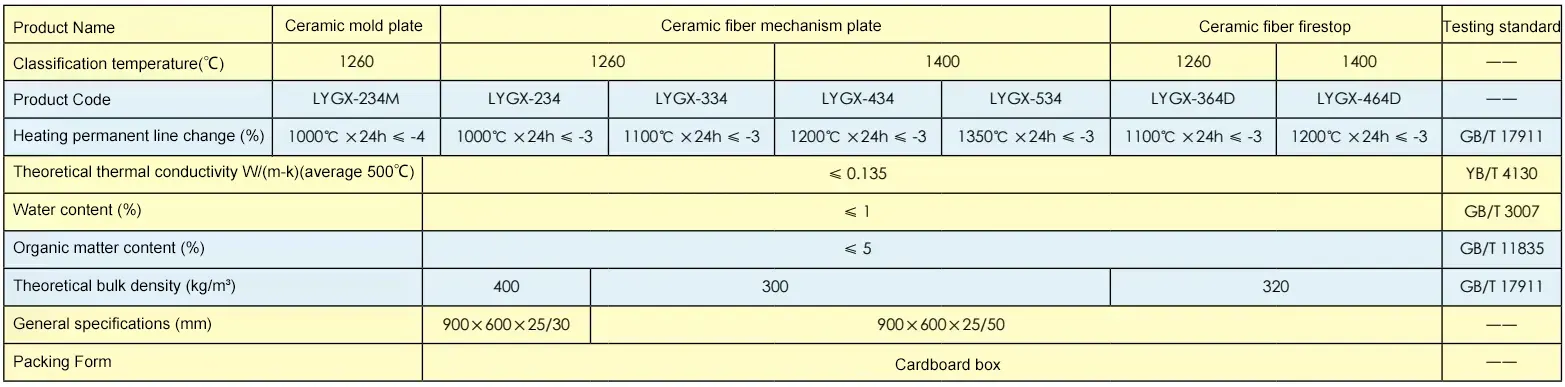

[ Main technical performance index ]

Note: The above data represent typical average values measured according to standard testing methods and are subject to variations under normal production fluctuations. These data are provided as part of a technical service and may be subject to adjustments; as a result, they should not be considered as product indicators.

Related Products